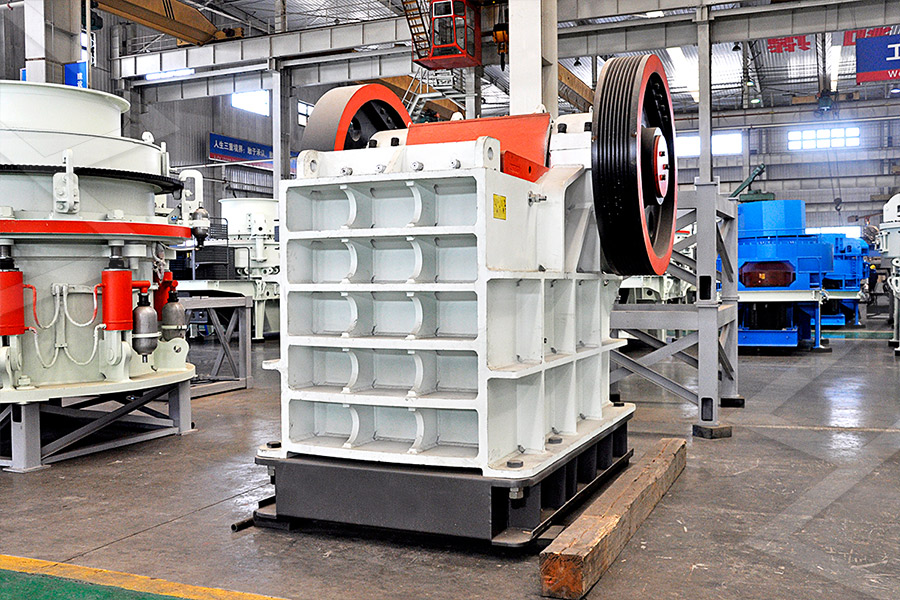

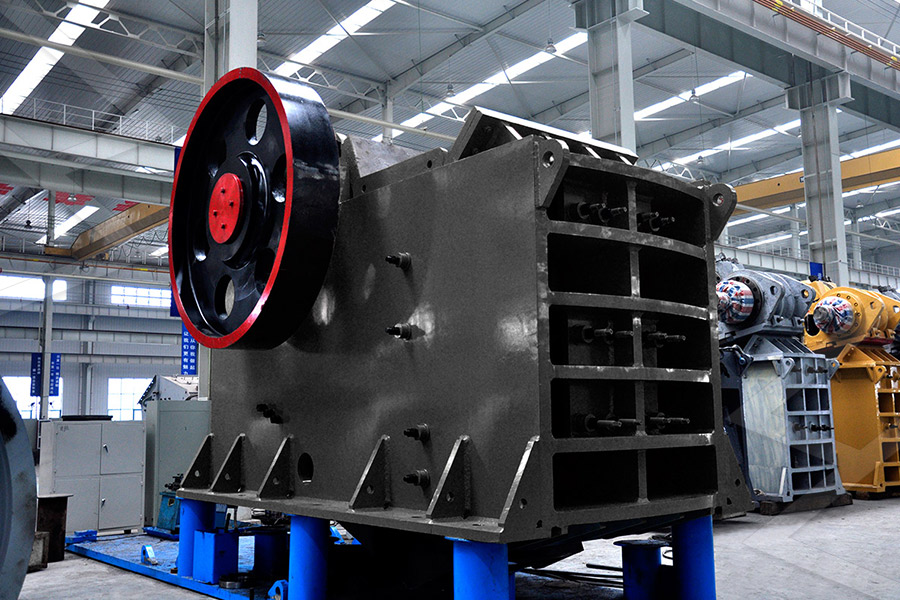

Nickel Jaw Crushersnickel Laterite Feeder

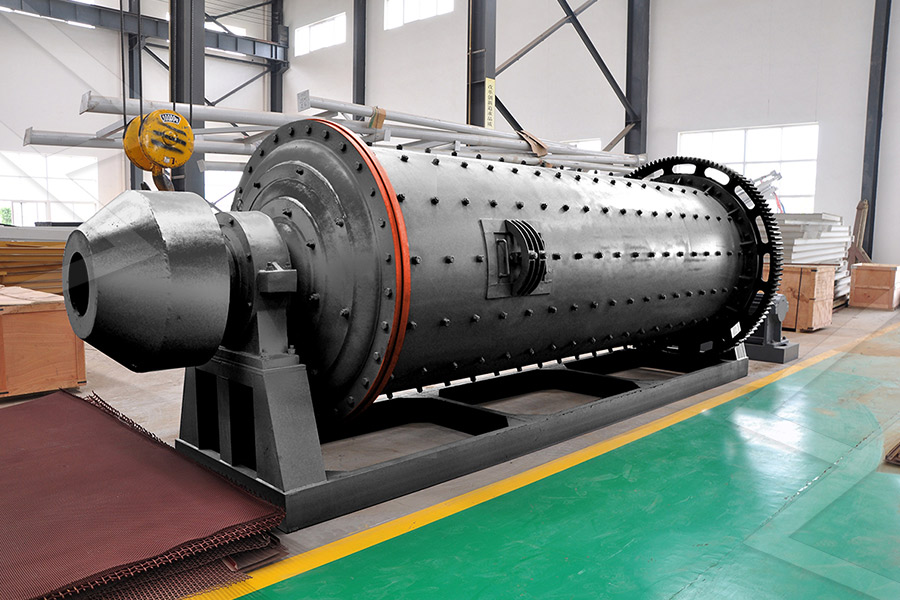

Nickel Ore Processing Plant JXSC Mineral

2024年12月30日 Nickel ore divides into nickel sulfide ore and nickel oxide ore (laterite nickel ore) The Main beneficiation process of nickel sulfide is flotation, and the subsidiary process is About Placer Gold Placer gold refers to the gold formed by the rock gold in the Placer Gold Mineral Proces2024年11月1日 Saprolitic nickel laterite ore, with its high nickel content and low iron content, is more suitable for pyrometallurgical processes In contrast, limonitic nickel laterite ore, Review on comprehensive utilization of nickel laterite ore2017年8月15日 Nickel (Ni) laterites are characterised by low Ni grades, complex mineralogy and high moisture contents which have significant technical and economic impacts on their Preconcentration strategies in the processing of nickel laterite

.jpg)

Preconcentration strategies in the processing of nickel laterite

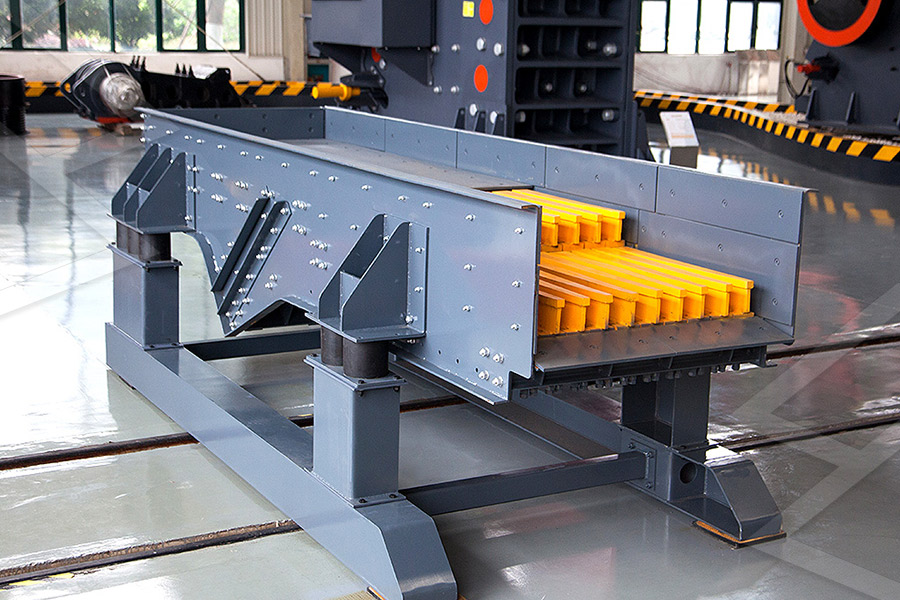

2015年8月1日 By far the most common preconcentration process used ahead of commercial hydrometallurgical processing of Ni laterites is the removal of a coarse fraction from the feed 2024年12月26日 Nickel ore primarily occurs in two forms: laterite and sulfide deposits Laterite ores: Found near the earth's surface, typically in tropical climates They are rich in iron and Nickel Processing Flow: Comprehensive Guide Mining Pedia3 天之前 Nickel ores mainly include coppernickel sulfide ore and nickel oxide ore (laterite nickel ore) The most important is the nickel ore flotation process, magnetic separation and Nickel Ore Beneficiation Plant JXSC 2024年1月5日 Key topics to be discussed include enhancements in the mineralogical characterisation, beneficiation approaches, improvements in the understanding and DEVELOPMENTS IN THE HYDROMETALLURGICAL

Nickel industry Part 2 Processing nickel laterites and

2024年8月7日 Laterites make up over 70 % of both nickel production and known terrestrial resources today and have been the fastest growing source of nickel for some time In Part 2 of 2016年1月1日 Leaching of nickel laterite ore at atmospheric pressure is a leaching method that can be operated at >100⁰C temperatures in an atmospheric pressure, which is applicable to a lowgrade(PDF) Hydrometallurgical processing of nickel 2021年10月24日 Nickel laterite ore is used to produce nickel metal, predominantly to manufacture stainless steel as well as nickel sulfate, a key ingredient in the batteries that drive Nickel Laterites—Mineralogical 2013年4月15日 Nickel laterite ores account for over 60% of global nickel supply They are the product of intensive deep weathering of serpentinites under humid tropical conditions (PDF) Nickel Laterite Ore Deposits:

(PDF) NickelCobalt Laterites—A Deposit Model

2020年4月16日 Nickelcobalt (NiCo) laterite deposits are supergene enrichments of Ni±Co that form from intense chemical and mechanical weathering of ultramafic parent rocks These regolith deposits typically 2016年1月1日 Leaching of nickel laterite ore at atmospheric pressure is a leaching method that can be operated at >100⁰C temperatures in an atmospheric pressure, which is applicable to a lowgrade laterite ore(PDF) Hydrometallurgical processing of nickel Actions Automate any workflowen/115/mining jaw track crushernickel ore crushermd at 2024年11月11日 Fluidized reduction roasting is an efficient metallurgical technique However, its application to nickel laterite ore has rarely been reported In this paper, the effects of reduction temperature, reduction time, Characterization of fluidized reduction roasting

(PDF) Characteristics and Controlling Factors on

2023年6月30日 Regional characteristics on nickel laterite deposits in Sulawesi are understood based on various exploration activities such as outcrop, trench and pit survey, petrological observation 1987年1月1日 Australia has large reserves of limonite and claybased laterites that are currently underutilized This review summarizes the latest nickel laterite upgrading studies reported in the literature (PDF) Treatment of laterite ores of nickel to 2023年10月17日 The dried sample was then subjected to a crushing process using a jaw crusher (XPC 125 × 100), Nickel laterite ore with 788 wt% coal, 12 wt% calcium sulphate reduced at 1200 °C for 30 min HighGrade Ferronickel Concentrates Prepared 2023年1月19日 Nickel is a kind of silvery white ferromagnetic metal firstly separated by Swedish mineralogist AF Cronstedt in 1751 It is in the eighth group of the fourth period in the periodic table of elements, with atomic An Overview of Nickel Utilization from Laterite

Mineralogical controls on the Ni and Co recovery from

2024年10月21日 The laterite ores (saprolitic laterite 1, SL1; limonitic laterite 1, LL1; saprolitic laterite 2, SL2; and limonitic laterite 2, LL2) are mainly rich in SiO 2, Fe 2 O 3, Al 2 O 3, and You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('') and can be up to 35 characters longsbm/sbm grizzly mining nickelmd at master sbm2022年6月11日 The nickel content and mineral composition of different deposits vary widely Therefore, it is difficult to enrich by traditional beneficiation processes At present, the beneficiation processes of laterite nickel ore How to Process the Laterite Nickel Ore? Xinhai 2010年1月1日 Nickel laterite occurrences in Turkey have a Feoxide dominated mineralogy and average 1–15% nickel grade Although none of them is a worldclass deposit there are still largescale investments Progress in understanding the evolution of

.jpg)

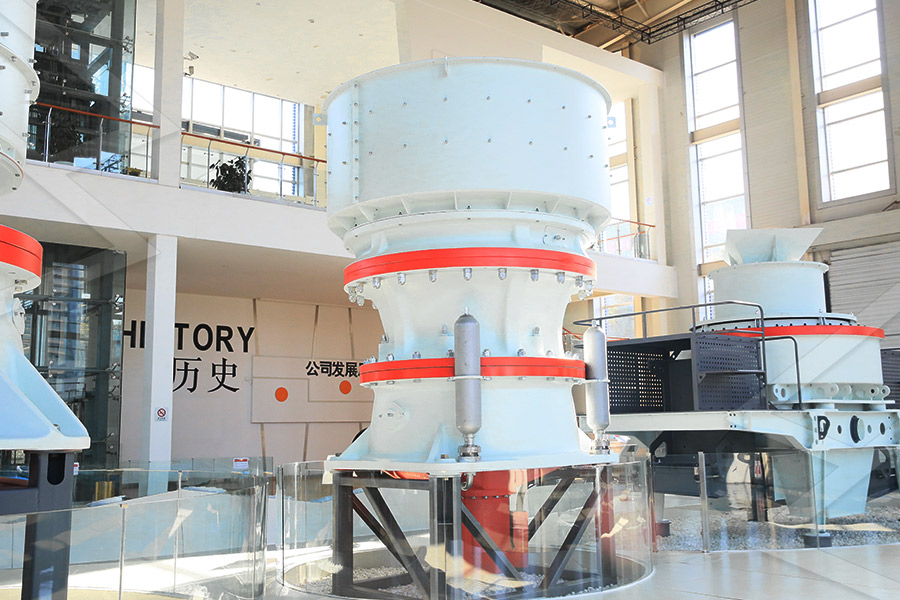

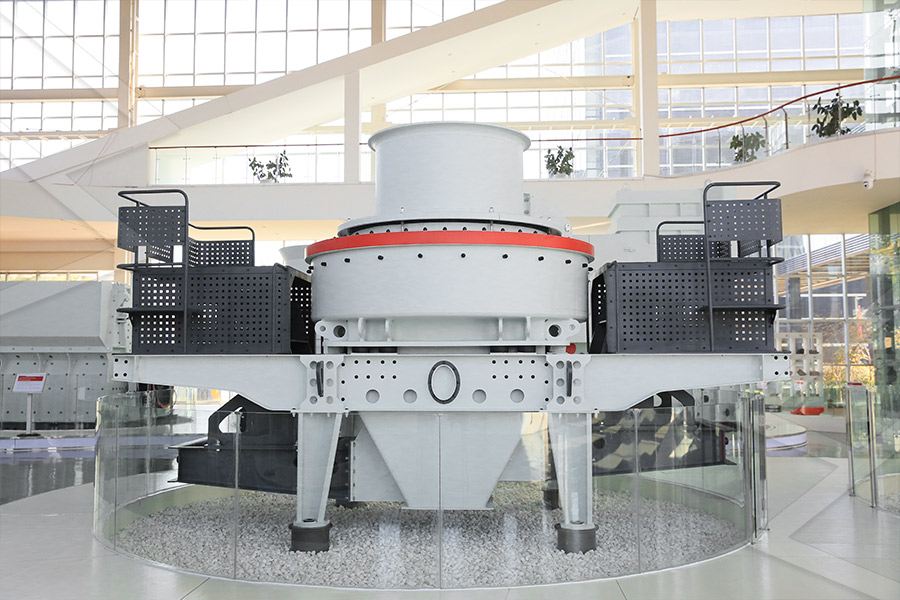

(PDF) Nickel Laterite Smelting Processes and Some

2019年9月3日 pyrometallurgically (ferronickel and ferronickel with lowNickel content), hydrometallur gically (pressure acid leaching), or both (Caron process) Historically , the 2017年5月1日 The main source of nickel has gradually become the recovery of ferronickel concentrate from lowgrade laterite nickel ore In this work, highgrade ferronickel concentrate was prepared by a Twostage reduction for the preparation of The nickel laterite in upper layer of the ore deposit, with higher content of iron (Fe) and lower content of silica (SiO 2) and magnesium (Mg) in general, belongs to the limonite type, and Nickel Laterite Metallurgy SpringerLink2002年1月1日 This paper reviews the nature and genesis of nickel laterite mineralisation, and describes the relationship between deposit characteristics (both geological and non (PDF) Nickel laterite deposits –

.jpg)

Preconcentration strategies in the processing of nickel laterite

2015年8月1日 Li et al (2009) investigated the effects of preroasting on the leaching of Chinese Ni laterite ores, and Rhamdhani et al, 2009a, Rhamdhani et al, 2009b investigated the 2023年8月31日 The hydrometallurgical process of nickel laterite leaves a residue that still contains valuable elements Its utilization can improve overall process efficiency and reduce environmental damageValorization of Solid Residue from the Lateritic 2022年3月15日 The runofmine (ROM) (20 kg) was crushed by jaw crusher and then by hammer mill to under 28 mm Then, the ROM ore was sampled by coning and quartering Chemophysical concentration of a Lowgrade nickel laterite 2015年4月7日 Australia has large reserves of limonite and claybased laterites that are currently underutilized This review summarizes the latest nickel laterite upgrading studies reported in the literature Preconcentration strategies in the processing of

Nickel laterite deposits – geological overview, resources

2024年6月26日 Most lateritic nickel resources occur within a band about 22 degrees of latitude either side of the equator (Fig 1) and the giant, and in some cases highest grade, deposits are The Metso Nickel Laterite Leaching Process provides a HPAL processing method for nickel and cobalt containing laterites Our Autoclave Plant Unit and VSF®X Plant Unit are the basis of the process and guarantee high Nickel Laterite Leaching Process MetsoContribute to brblmd/sbm development by creating an account on GitHubsbm/sbm nickel ore jaw crusher suppliermd at main2023年5月28日 The nickel laterite in upper layer of the ore deposit, with higher content of iron (Fe) and lower content of silica (SiO 2) and magnesium (Mg) in general, belongs to the Nickel Laterite Metallurgy SpringerLink

Preparation of highgrade ferronickel from lowgrade nickel laterite

2020年6月1日 Nickel laterite with a C/O = 12 and an additive of 4 wt% CaF 2 was reduced for 25 min at 1200 °C, and an overview of the particles/phases in the reduced nickel laterite is 2020年2月28日 The processing of nickel laterites by high pressure acid leaching (HPAL) typically uses feeds with an average nickel content not less than 11%–12% (cutoff grade The High Temperature CoProcessing 2020年5月1日 Deportment and implication of the MLA data of nickel in the laterite paleosol The geochemical characteristics and Ni distribution in the Northern Oman laterite deposits has Mineralogical characterization of lowgrade nickel laterites 2021年10月24日 Nickel laterite ore is used to produce nickel metal, predominantly to manufacture stainless steel as well as nickel sulfate, a key ingredient in the batteries that drive Nickel Laterites—Mineralogical

.jpg)

(PDF) Nickel Laterite Ore Deposits:

2013年4月15日 Nickel laterite ores account for over 60% of global nickel supply They are the product of intensive deep weathering of serpentinites under humid tropical conditions 2020年4月16日 Nickelcobalt (NiCo) laterite deposits are supergene enrichments of Ni±Co that form from intense chemical and mechanical weathering of ultramafic parent rocks These regolith deposits typically (PDF) NickelCobalt Laterites—A Deposit Model 2016年1月1日 Leaching of nickel laterite ore at atmospheric pressure is a leaching method that can be operated at >100⁰C temperatures in an atmospheric pressure, which is applicable to a lowgrade laterite ore(PDF) Hydrometallurgical processing of nickel Actions Automate any workflowen/115/mining jaw track crushernickel ore crushermd at

Characterization of fluidized reduction roasting

2024年11月11日 Fluidized reduction roasting is an efficient metallurgical technique However, its application to nickel laterite ore has rarely been reported In this paper, the effects of reduction temperature, reduction time, 2023年6月30日 Regional characteristics on nickel laterite deposits in Sulawesi are understood based on various exploration activities such as outcrop, trench and pit survey, petrological observation (PDF) Characteristics and Controlling Factors on 1987年1月1日 Australia has large reserves of limonite and claybased laterites that are currently underutilized This review summarizes the latest nickel laterite upgrading studies reported in the literature (PDF) Treatment of laterite ores of nickel to 2023年10月17日 The dried sample was then subjected to a crushing process using a jaw crusher (XPC 125 × 100), Nickel laterite ore with 788 wt% coal, 12 wt% calcium sulphate reduced at 1200 °C for 30 min HighGrade Ferronickel Concentrates Prepared

An Overview of Nickel Utilization from Laterite

2023年1月19日 Nickel is a kind of silvery white ferromagnetic metal firstly separated by Swedish mineralogist AF Cronstedt in 1751 It is in the eighth group of the fourth period in the periodic table of elements, with atomic